Particular About Hiire (Heating)

Proud of our original method for Hiire

We are proud of our original method for Hiire, means to heat brewed sake for the purpose of pasteurization.

Especially, the first start of pasteurization, called Hon-Hiire, our style is quite different from the others.

The temperature of brewed Sake is heated from 70 degrees Celsius to 75 degrees Celsius. After heating, Sake is pushed

into the tank. When the tank is full, the hose, used to push Sake into the tank, plugged off and water is sprinkled to cool down for sterilization of Hiochi bacteria, which deteriorates Sake.

This style is well known and written on the textbook.

This is a traditional style to preserve Sake at a room temperature when there was no refrigerator at that time

This method is good enough in safety, however, not good at all, in taste and fragrance points of view.

This style made a botch of taste and fragrance in exchange for costs and safety.

Now let’s review together.

Usually, it takes 30 to 40 minutes to full the tank with 10,000 litter 70 degree Celsius sake. It also takes a half day or full day to cool down to 15 degree Celsius.

This method breaks the original taste and fragrance.

I think you can understand, if you want to drink Sake with hot and fresh conditions. However, this method only allows you to drink a cold status after a half day from hot condition.

In this method, we are afraid that the original “that wonderful taste when squeezed,” will far away.

Plate Heater Rapid Cooling and Warming

In this reason, we review our heating process.

We deployed the new process, called “Plate Heater Rapid Cooling and Warming” for all sake, expect DaiGinjyo.

This method is based on the idea that the temperature of original sake heats up to 60 to 65 degree and cools down up to 10 degree rapidly.

In short, the concept of this idea is shortening the time for the sake to be hot.

As for the time, it takes only 1 minutes during 65 degree to 10 degree for 1L sake.

Comparing to the usual way, it can be used with a short time.

“Plate Heater” is the name of machines to be used for heating up the sake.

We used 3 plates to heat.

The cold original sake before heating is to be set on the middle plate.

The sake, 5 degree, is to be heat up to 65 degree with hot water on the left plate.

The warmed sake is back to the middle plate and mixed with original sake before heating, 5 degree, and rapidly cool down up to 35 degree.

Sake is to cool down up to 10 degree at the moment with the right plate with inside cold water circulation mechanism.

In this process, the sake is rapidly heated up to 65 degree and also cooled down 10 degree at once.

Thanks to this process, it is possible to keep the high quality of preservation, because we can keep the taste of sake with fresh and fruity and also prevent the “NAMAHINE”, goes slack peculiar sweet taste without providing the enzyme.

But, in this process, it is not possible to sterilize all of the “fire fall fungi”, which rotten the sake.

This is due to the reason that we cannot sterilize the tank itself.

In usual case, it is possible to sterilize the inside of tank with full of hot sake.

In this new method, it is not possible to sterilize the inside with 10 degree’s cold sake and it is also required to keep under 10 degree in order not to activate the “fire fall fungi” even in case it alive.

It is mandatory to be in refrigerated-store.

In addition, it is also required to heat again when putting into the bottle, even if it is stored under 10 degree.

There is a possibility of being cloudy and spoiled, we have to take great care not to put into the bottle at room temperature, and we must ship with chilled condition if it is being stored in a bottle.

We think this is the one of the best method of heating.

We are looking forward for the future outlook, because the numbers of brewery to deploy our method is growing.

To be honest, at first, we suspected the machine was out of order and Sake was not heated at all.

The first Sake heated by this method was almost the same taste and quality of the original one.

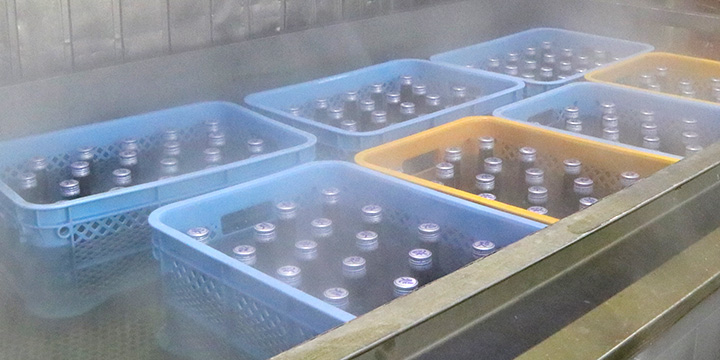

Bottle Storage in case for the small amount of sake

In addition, we use Bottle Storage for DaiGinjyo, Jyunmai DaiGinjyo and Jyunmai Ginjo.

We use Bottle Storage in case for the small amount of sake and to avoid the possibility of spoiling within the tank storage and want to promote good fragrance and prevent from spoiling of taste, not heating twice, but one time.

This method of heating is common among the brewery across the country in Japan.

We also use Bottle Storage for the sake to be heating one time and for the small amount of sake.

Now we will explain how to heat Bottle Storage.

This is the method that original sake is being put into a bottle, and put it in hot water to heat up to 60-65 degree and put it in cold water to cool down rapidly.

It takes almost 20-25 minutes for Sho bottled sake to heat up to 60-65 degree and also takes 15-20 minutes to cool down to 10 degree.

Comparing to “Plate Heater”, it takes longer time, but

We think heating once is the best, because it promote good fragrance and it prevent from taste spoiling.

The Bottle Storage sake is moved quickly and stored into the refrigerator, put out and shipped with the label on the surface of bottle.

Timing of heating is more important

We have explained how to heat. Indeed it is important but the timing of heating is more important.

We used to make sake at one time and heat all of sake and store it in winter season before the group of chief sake brewer goes back home in spring.

It used to store the original sake as much as possible, and heat it all together after finishing to make sake.

It was very effective because we can focus on our work after the group of chief sake brewer finish their job.

However, nowadays, that heat timing is too late. It causes bad due to “NAMAHINE”, goes slack with peculiar sweet taste.

It is a basic concept for sake of modern to heat as soon as possible after squeezing.

The earlier the timing of heating, the better the taste, because it helps to fix the flavor inside not only for DaiGinjyo, but also for Junmaishu and Honjyojosyu.

Here, we can show you the details of the timing for heating as below table;

| DaiGinjo・Jyunmai Ginjo | Within the past 3– 7 days after squeezing. |

|---|---|

| Jyunmai Ginjo・Ginjo | Within the past 7– 14 days after squeezing. |

| Special Jyunmai | Within the past 10– 20 days after squeezing. |

| Honjozo | Within the past 10– 20 days after squeezing. |

| Normal sake | Within the past 30 days after squeezing. |

We know that it is our duty to keep the timing of heating exactly, because it is one of the most important process for making sake.

If Hire is not conducted, sake deteriorates very quickly, and soon generates Namahineka.